System Dynamics Of

Human Resource And Knowledge Management

In Engineering

Education

Lewlyn L. R. Rodrigues, Morvin Savio Martis,

Manipal Institute of Technology

ABSTRACT:

This paper simulates a time-based

dynamic model to fill the competence gap of engineering graduates, based on the

governing system variables. System dynamics is employed to illustrate relations

between graduation, recruitment, knowledge transfer, and knowledge loss rates

in causal form. Graphs are plotted to estimate the actual competence pool of

engineers, competence training completion rate and actual level of competence

absorbed, under the dynamic conditions of the governing time-based policy

parameters. Through the simulation results thus obtained, suggestions are made

for effective control of policy parameters of HR & KM system

1. Introduction

There has been a

proliferation in higher education in general, and engineering education in

particular, as it has a direct bearing on the economy of the country. But

maintaining a balance between supply and demand is always a challenging task.

Unless the engineering institutes produce engineers who are employable in the

market or be entrepreneurs, these large number of engineering institutes will

be mere unemployment producing centres.

Human resource planning has

always been a challenging task at the micro or macro levels in a country.

Time-based dynamic analysis would be of great help in strategic human resource

planning. At the same time, the transition from industrial economy to knowledge

based economy, has necessitated an efficient knowledge management (KM) at the

national level. Hence, the time is now ripe to dynamically analyse human

resource management (HRM) and KM through the development of an integrated

model.

ISO implementation in

service industries has brought the term ‘core competence’ into the doorsteps of

engineering institutes. Baker et al (1997), define ‘competence’ as the set of

skills and knowledge that an individual needs in order to effectively perform a

specified job. In engineering educational context, core competence to be

possessed by the future engineers would be the knowledge, skill and attitude to

be employable in the market or turn-out to be entrepreneurs. Despite the fact

that this core competence has to be developed during the four year period of

graduation studies, some may take less time (be employed during the third year

itself through campus placements) or some may take more time than four years.

This doesn’t rule out the possibility of rejection of the course by the

students during the study, or take up higher studies after the graduation.

System dynamics could be of

a powerful tool in competence pool mapping for varying values of competence gap

recovery time (Tr), competence loss rate averaging time (Ta),

competence training delay time (Tdt) and recruitment delay time (Tdr).

The term ‘competence’ used in the engineering educational context includes-

knowledge, skill and attitudes of the engineers/future engineers that would

enable them to be employed in the global market, join for higher studies, or

become entrepreneurs. Competence loss refers to the failure of the students to

be employable, pursue higher studies or become entrepreneurs.

The various specialized

nomenclature used in this paper are defined in Appendix 1.

2. Objectives

Of The Study

This paper has the

following objectives:

·

Develop

causal loop diagram for KM of an engineering education system.

·

Develop

the flow diagram of competence pool model (COPM) based on the above causal loop

diagram.

·

Derive

the governing equation of COPM based on which the system dynamics block diagram

of COPM is developed.

·

Simulate

the 3-dimensional graphs and generate the performance index table for the

dynamics of KM & HRM.

The model thus developed

would give the conditions for optimum performance of KM & HRM initiatives,

thus contributing to the policy scenario building and improvement on a

continual basis.

3. Literature

Review

Engineering institutions

are basically the knowledge repositories which exist to impart the required

level of competence in the future engineers by imparting the underpinning

knowledge, skills, attitudes, values, ethics and all other characteristics

demanded by the engineering profession. Hence, the institutes should be

equipped to transfer both ‘explicit’ and ‘tacit’ knowledge (Nonaka &

Takeuchi, 1995; Routledge, 2000) to the future engineers through the well

planned and organized curriculum.

Human Resource Management

(HRM) mainly involves planning, which involves five stages viz., analysis of

the system, deciding the time horizon of the plan, forecasting the demand for

and supply of manpower, reconciliation, and preparation of action plans

(Tripathi, 2002). So, the study of the system forms the very first phase of the

HRM. This issue is of national significance as the economy of the country is

now tied to the database of the knowledge workers in this knowledge based

economy.

Defining

KM is not only problematic but also varies from person to person based on the

context and use (Neef, 1999, Bhatt; 2001, Raub & Rulling 2001). Turban

& Aronson (2002), describe KM as a process that helps organisations

identify, select, organize, disseminate, and transfer important information and

expertise that are part of the organisational memory that typically resides

within the organisation in an unstructured manner. We select only this

definition as it is most appropriate in the context of this paper.

System Dynamics (SD) is

basically built upon traditional management of social system, cybernetics and

computer simulation (Sushil, 1993). SD

is based on the philosophy that the behaviour of a system is principally caused

by its structure based on policies & traditions; and the structure of an

organization can be best represented in terms of underlying flows of various

resources cutting across the functional departments tracing across various

feedback loops, delays and amplifications in the system. Hence, a SD model

typically consists of ‘causal loop’ and ‘flow diagram’. The causal loop depicts

causal hypothesis during model development, so as to make the presentation of

the structure in an aggregate form, whereas, flow diagrams represent the

detailed flow structure of the system in terms of the fine policy structures so

as to facilitate the development of the mathematical model for simulation

(Coyle, 1977).

4. Research

Methodology

The research methodology is based on

the SD methodology proposed by Forrester (1961) and is depicted in Figure 1.

The research methodology is based on

the SD methodology proposed by Forrester (1961) and is depicted in Figure 1.

Fig. 1: Research Methodology

To start

with, we performed the situation analysis, which included problem

identification i.e. KM & HRM dynamics in engineering education and the

study of the number of engineers produced in the country per year and their

absorption rate. We then developed the causal loop diagram for KM & HRM

(Figure 2). Jay Forrester (1961) did the pioneering work of system dynamic

theory. Senge (1994) has used this theory very widely in developing the concept

of Learning Organisation. Through the reference of these two, we developed the

causal loop diagram (Figure 2). This considered the parameters which have

significant influence on knowledge, skill and attitude development that

provides the required level of competency to the engineers. We also considered,

absorption of these engineers based the competency thus gained. A sustainable

development of engineering competence has been the focus in the development of

causal relations, as engineers who fail to develop the required level of

competency to be absorbed in the market add to ‘competence loss’, which is in

turn detrimental to the growth of the country. Various influences are

represented in the form of feed-forward and feedback loops. A computer

simulation of this model is possible but is of limited use as the individual parameters

change (e.g. recruiting rate) cannot be isolated easily (Hafeez &

Abdelmeguid, 2003).

The next stage was to

develop the Flow Diagram (Figure3). This mainly illustrates the feedback (based

on competence gap) and feed-forward control (based on forecast competence loss

rate). In order to analyse the dynamic response we have taken time-based policy

variables Ta, Tr , Tdt and Tdr as indicated in the flow diagram.

During the

ideal operation, the number of graduates produced equals the number of

graduates absorbed in the market. But the problems arise when all the admitted

graduates fail to acquire the required level of competence, and also, the

market requirement for the skilled engineering graduates change due to several

other governing factors, as a result of which, the recruitment may also be

denied/delayed. So the above four policy parameters (Ta, Tr,

Tdt, & Tdr) are to be varied to determine their

optimum setting using simulation results. The influence of these parameters on

the Competence Pool, Competence Training and Absorption Rate would provide

useful input for policy makers.

Figure 3: Flow Diagram of

COPM

The governing equations

giving discrete-time feed-forward and feedback difference equations used to

calculate the system parameters are given in Appendix 1. The block diagram

representation of the COPM is shown in Figure 4. We have used MATLAB Version

6.5 software to produce the simulation.

The purpose of the entire

system is to match the desired level of competence pool required with the

actual level of competence pool absorbed. To achieve the desired level of

competence pool, a simple appropriate policy is proportional control, where

information containing the magnitude of the level (in the present case the

competence pool) is fed back to control the competence training rate (Hafeez

& Abdelmeguid, 2003). The competence training rate may be calculated by

dividing the discrepancy between the desired and actual value of the level by a

time factor, which represents the average delay in performing the training rate

(Appendix 1).

The policy parameters Ta,

Tr, Tdt and Tdr are varied to determine their

optimum settings using the simulation results. Once the initial conditions are

set the system automatically simulates results for reaching the desired

competence pool. We have taken the desired level of skill pool to be 250,000

engineers out of whom nearly one fourth i.e. 62,500 are unemployed which is

considered as the competence loss (Sheshagiri, 2004). We have taken a delay

time in training of 6 months to enable them to get the required competence

level through training. We consider a drop out of about 5% of engineers, which

includes the candidates leaving the course for all possible reasons. Therefore,

the simulation model is subjected to some 20% increase in the present

competence as shown in Figures 5a & 5b respectively.

5. Results

& Findings

The simulation results are

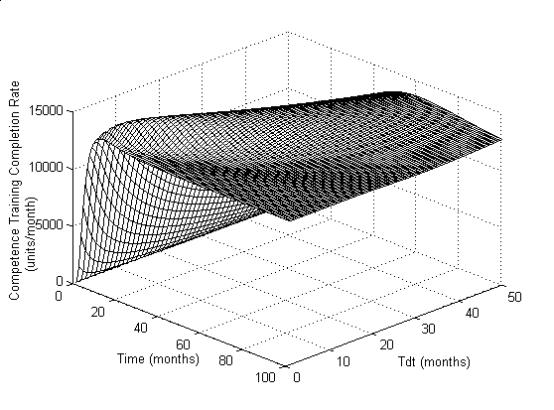

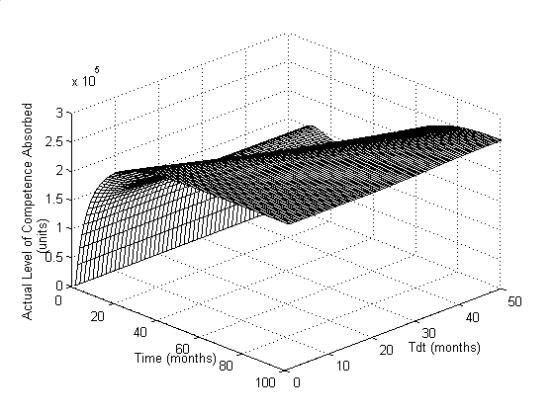

shown in the Figure 5 – 8. The Figures 5a, 5b, 5c shows the response of Actual

Engineers Competence Pool Level, Competence Training Completion Rate and Actual

Level of Competence Absorbed for a range of Tr values.

Figure 5a: Step response of

COPM for varying values of Tr

Figure 5b: Step response of

COPM for varying values of Tr

Figure 5c: Step response of

COPM for varying values of Tr

In the worst case (Figure 5a);

the system would take 80 months to recover the competence loss if Tr

is more than about 30 months. On the other hand, a small value of Tr would

allow a quick competency recovery (about 5 months). But if Tr is

fixed to be very small, unwanted oscillation in the competence skill pool may

result for a long period (about 35 months). Hence, we can conclude that Tr

has a higher influence on the system than the other policy parameters.

Moreover, as per control theory this constitutes a bad system, as number of

oscillations are supposed to be as minimum as possible.

The Figures 6a, 6b and 6c

illustrate the influence of Ta (Competence gap loss rate forecast

averaging time) to control the HR and KM policy.

Figure 6a: Step response of

COPM for varying values of Ta

Figure 6b: Step response of

COPM for varying values of Ta

Figure 6c: Step response of COPM for varying values

of Ta

The Figure 6a shows that as

Ta is gradually increased, the overshoot becomes well managed but it

also shows that it takes a very long time (about 40 months) to settle, which is

unacceptable under any circumstances. Figure 6b illustrates that increasing Ta

decreases the peak value, thus the competence-training rate takes longer

time to settle, indicating that Ta has significant influence on the

system. Similarly, figure 6c shows that increasing Ta slightly

increases the time for rise.

The Figures 7a, 7b and 7c

illustrate the influence of Tdt.

Figure 7a. Step response of COPM for varying

values of Tdt

Figure 7b: Step response of

COPM for varying values of Tdt

Figure 7c: Step response of

COPM for varying values of Tdt

Smaller the Tdt values,

quicker will be the competence pool recovery (Figure 7a). For values of Tdt

upto 8 months, slight rise in Tdt will cause increase in

competence training completion rate (Figure 7b). Figure 7c shows that

increasing Tdt slightly increases the time for rise, thus taking 70

months to settle, which is also unacceptable.

Figure 8 shows the response

of Actual Level of Competence Absorbed for varying values of Tdr .

Figure 8: Step response of COPM for varying values of

Tdr

Smaller values of Tdr

may allow quicker settling of the competence absorption, but at the same time induces

unwanted oscillations, however, graph indicates that 3 – 6 months would be

ideal. The detailed explanation of performance index based on the policy

parameters is given in Table 1.

|

|

COPM

Design Parameters |

||||

|

Performance Index |

|

Tr |

Ta |

Tdt |

Tdr |

|

Actual Engineers Competence Pool Level |

Initial competence pool drop |

Increasing Tr

increases the initial competence pool drop |

Increasing Ta increases the initial competence pool drop |

Increasing Tdt increases the initial competence pool drop |

NA

|

|

Duration of competence pool deficit |

Increasing Tr increases the settling time |

Increasing Ta increases the settling time |

Increasing Tdt increases the settling time |

NA |

|

|

Peak competence pool overshoot |

Increasing Tr

decreases the peak Value |

Increasing Ta decreases the peak overshoot |

Increasing Tdt decreases the peak values |

NA |

|

|

Settling time |

80 months [Figure

5a] |

75 months [Figure 6a] |

73 months [Figure 7a] |

NA |

|

|

Graduation Completion Rate |

Rise time |

Increasing Tr

slightly increases the time

for rise |

Increasing Ta slightly increases the time for rise |

Increasing Tdt slightly increases the time for rise |

NA |

|

Peak Overshoot |

Increasing Tr

decreases the peak value |

Increasing Ta decreases the peak overshoot |

Increasing Tdt increases the peak value |

NA |

|

|

Duration of Overshoot |

Increasing Tr

slightly increases the time

for peak value |

Increasing Ta slightly increases the time for overshoot |

Increasing Tt slightly increases the time for peak value |

NA |

|

|

Settling time |

35 months [Figure

5b] |

55 months [Figure 6b] |

50 months [Figure 7b] |

NA |

|

|

Actual Level of Competence Absorbed |

Rise time |

Increasing Tr

slightly increases the time

for rise |

Increasing Ta slightly increases the time for rise |

Increasing Tdt increases the time for rise |

Increase in Tdr increases the time for rise |

|

Settling time |

60 months [Figure

5c] |

30 months [Figure 6c] |

70 months [Figure 7c] |

80 months [Figure 8] |

|

Table 1: Performance Index

for a range of policy parameters

6. Contribution

Of The Research

A large group

of researchers (Coyle, 1977; Towill, 1982; Cheema et al., 1989; Ferris &

Towill,1993; Mason et al., 1995; Hafeez et al., 1996) have very successfully

applied system dynamics in industrial system, customer service level,

production control system, supply chain management, and efficient consumer

response. This research work goes in similar lines and finds its use in

studying the KM & HRM dynamics in engineering education system. Engineering

is a very creative field, which encompasses the inculcation of a group of

abilities including analysis, synthesis, designing, evaluation,

experimentation, etc. Further, these skills are coupled with managerial and

leadership qualities during the course of study. Hence, the current trend is to

absorb engineers in IT industries irrespective of their branches. In fact,

engineering has now become one of the most sought after professions in Asian

countries, especially in India, where there has been a proliferation of

engineering education since the past two decades. So there is now a compelling

necessity to ensure that supply and demand balance with each other. In-built

checks and balances become very essential to fill the ‘competence gap’, which

by itself is dependent on several factors dealt in this study. Therefore this model

not only explains the system dynamics of engineering education system w.r.t. KM

& HRM but also explains in detail the effects of four basic policy

parameters viz. Ta, Tr, Tdt and Tdr.

7. Conclusions

And Scope For Future Work

Higher education in general

and engineering education in particular has a direct bearing on the economy of

a country (Wald, 2001), owing to the fact that it produces the technical human

resources who are responsible for the technological growth of the country.

Globalization has now made it imperative that there is a need to produce

engineers who are not only employable in the country but also meet the

international technical manpower requirements. So in this connection the KM

& HRM issues of engineering education become very important.

Our study is a direct

application of system dynamics into the KM & HRM issues of engineering

education. The results reveal that present and future competency gap can be

minimized through time effective competency training programmes. The COPM model

developed in this paper shows the effect of the policy parameters Ta,

Tr, Tdt and Tdr on the engineering

competence pool. The simulation also shows that the maximum time limit of 6

months to regain the competence loss could be very effective if the policy

parameters are controlled suitably.

Even though this model has

been developed for engineering education, its application may be extended to

other higher educational requirements. This study does not consider the effect

of feedback or feed-forward on the recruitment rate but focuses on the

development of engineering competence. So, the study may be further extended

based on the system dynamics of recruitment, considering all the influencing

factors such as socio-economical factors, influence of globalization,

technological growth rate etc.

8. References:

Baker, J., C., Mapels, J.,

New, C. C., 1997, A Hierarchical Model Of Business Competence, Integrated

Manufacturing Systems, Vol. 8; pp. 265-272.

Bhatt,

C., 2001, KM In Organizations: Examining The Interaction Between People,

Processes And Technology, Journal of KM, Vol. 5, No. 1; pp. 68-75.

Cheema, P., Towill, D., R.,

Bishop, B., 1989, A Combined Feed-Forward/Feedback ‘To-Make’ Model For A

Multi-Product Machine Shop, Proceedings of the 5th National

Conference on Production Research, Huudersfield: UK; pp. 101-105.

Coyle, R.G., 1977,

Management System Dynamics, John Wiley & Sons, London.

Ferris, J., S., Towill, D.,

R., 1993, Benchmarking A Generic Family Of Dynmic Manufacturing Ordering & Control

Models, Journal of Systems Engineering, Vol. 3; pp. 170-182.

Forrester, J. W., 1961,

Industrial Dynamics, Cambridge: MIT Press.

Hafeez, K., Abdelmeguid,

H., 2003, Dynamics Of Human Resources And Knowledge Management, Journal of the

Operation Research Society, Vol. 54; pp. 153-164.

Hafeez, K., Griffiths, M.,

Griffiths, J., Naim, M., M., 1996, System Design Of A Two-Echelon Steel

Industry Supply Chain, International Journal of Production Economics, Vol. 45;

pp. 121-130.

Mason-Jones, R., Towill,

D., R., Hafeez, K., 1995, Dynamics Of Pipeline Control, Proceedings of XIV

Operational Management Conference, Israel, 10-13 July.

Neef,

1999, Making The Case For Knowledge Management: The Bigger Picture, Management

Decisions, Vol. 37, No. 1; pp. 72-78.

Nonaka, I., Takeuchi, H.,

1995, The Knowledge Creating Company: How Japanese Companies Create Dynamic

Innovation, New York: Oxford University Press.

Raub,

S., Rulling, C. C., 2001, The Knowledge Management Tussle – Speech

Communication And Rhetorical Strategies In The Development Of KM, Journal of

Information Technology, Vol. 16, No. 2; pp. 113-130.

Routledge, 2000, Concise

Routledge Encyclopaedia of Philosophy, New York: Routledge.

Sheshagiri, M., 2004,

Gearing Up For The GATS, Education Times, Bangalore Edition, August, 16; pp. 11.

Senge, P., M., 1994, The

Fifth Discipline: The Art And Practice The Learning Organization, Doubleday:

New York.

Sushil, 1993, How To

Develop A System Dynamic Model?, System Dynamics, A Practical

Approach For Managerial Problems, ISBN: 81-224-0498-7, Wiley Eastern

Publication.

Towill D., R., 1982,

Dynamic Analysis Of An Inventory And Order Based Production Control System,

International Journal of Production Research, Vol. 20; pp. 671-687.

Tripathi, P., C., (Ed.),

2002, Acquisition Of Human Resources, Human Resource Development, Sultan Chand

& Sons, New Delhi.

Turban,

E., Aronson, J.,E., (Eds.), 2002, Knowledge Management, Decision Support Systems And Intelligent

Systems, Pearson Education, ISBN 81-7808-367-1.

Wald, M., 2001, Engineering

Education, Globalization & Learning Styles, International Journal of

Engineering Education, Vol. 17, No. 1, UK: Tempus Publication ISSN 0949-149X;

pp. 1.

Appendix 1

Nomenclature Used In This paper

- CPG = Competence Gap.

- COPM = Competence Pool Model

- DECPL = Desired Engineers

Competence Pool Level = 250000 units.

- AECPL = Actual Engineers

Competence Pool Level.

- CTRATE = Competence Training

Rate.

- FGCFR = Forecast Graduate

Competence Fail Rate.

- Tr = Time over which the

competence gap is to be recovered.

- Ta = Average time to

determine the forecast competence loss rate.

- PGCFR = Present Graduate

Competence Fail Rate.

- CTCRATE = Competence Training

Completion Rate.

- Tdt = Competence Training Delay Time.

- ALCA = Actual Level of

Competence Absorbed.

- Tdr = Recruitment

Delay Time.

Appendix 2

Equations Used In This Study

- CPG = DECPL -AECPL

- CTRATE = CPG * (1/ Tr )

+ FGCFR

- CTCRATE = CTRATE * (1/ (1 + Tdt * S))

- 4. AECPL = (1/S) * (CTCRATE

- PGCFR)

- FGCFR = PGCFR * (1/ (1 + Ta

* S))

- ALCA = AECPL * (1/ (1 + Tdr

* S))

- AECPL/PGCFR = (Tr) *

((Tdt+ Ta)*S + (Tdt*Ta*S2))

/ ((1 + Ta*S)(1 + Tr*S + Tr*Tdt*S2))

- CTRATE/ PGCFR = (1+ (Tr+

Ta)*S)/ ((1 + Ta*S)( 1 + Tr*S + Tr*Tdt*S2

))

About the Authors:

Mr.

Lewlyn L. R. Rodrigues is a Ph.D. scholar in Knowledge Management & Human

Resource Management at Manipal Academy of Higher Education, Manipal, India. He

is widely pub;ished and is the recipient of several best paper awards and

‘Award of Excellency’ from the Labour and Social Affairs, Bahrain.

Lewlyn L. R. Rodrigues

B.E(Mech.), M.Tech.(Prodn. Engg.) Ph.D. Scholar, Faculty, Dept. of Mechanical

& IP Eng., Manipal Institute of

Technology, Manipal 576104, Karnataka India; Email: rodrigusr@yahoo.com;

Telephone: +91-0820-2571061-70 Ext. 24042; Mobile: 091-9845218118; FAX: +91-0820-2571061-71

Mr.

Morvin Savio Martis, is a M.Tech. student at Manipal Institute of Technology

working on his thesis under the guidance of Mr. Rodrigues. He is B. E. in Mechanical

Engineering. His is currently working on his dissertation of M.Tech. in

Engineering Management on System Dynamics of HRD & KM.

Morvin

Savio Martis B.E.(Mech.), III Sem. M.Tech., Dept. of Mechanical & IP

Eng., Manipal Institute of Technology, Manipal 576104, Karnataka India; Email: oceanmartis@yahoo.com; Telephone:

+91-0820-2571061-70 Ext. 24042; Residence: 091-0824-2248078; FAX:

+91-0820-2571061-71